Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

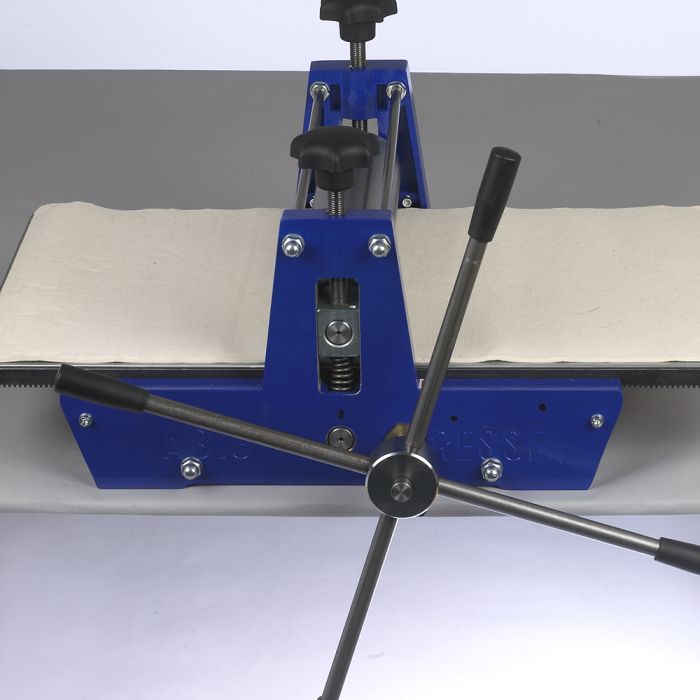

Gear Drive Professional Printing Presses

The difference between these printing presses and our lower cost P690 presses is that this printing plate will move through the press without the aid of the pressure from the top roller. This is important if you intend to work with collagraphy so that the roller won't crush your master plate. The press plate moves along with the aid of cogs and teeth on the underside of the plate bed. Not only will you be able to work with lino, etching plates and woodcut but also corrugated board plates for collagraphy as well as styrene foam plates which are prone to damage and design distortion with too much downward pressure. These presses are manufactured to the same high specification as our P690 presses so you can expect a cast aluminimum frame fitted with 80mm diameter steel pressure rollers which give a press force of 1000kg. The 2.7:1 ratio gearbox makes the handle turn more easily. The distance between the top roller and the plate bed can be adjusted to maximum of 18mm allowing thicker etching plates/wood blocks to be used with this press. The plate bed is covered with a 2.5mm thick zinc plate to ensure longevity and a smooth running surface.

Each press is supplied with a plate bed and felt blanket and four bolt holes for bench top fitting.

| Catalogue Page Number | Dryad Education 2022 |

|---|